In a significant leap forward for electrical engineering and materials science, researchers at Stanford University have unveiled a new ultrathin conductor, niobium phosphide, that surpasses copper in conductivity, particularly in films that are just a few atoms thick. This innovative discovery holds the potential to revolutionize the future of electronics by enhancing energy efficiency and performance.

What is Niobium Phosphide?

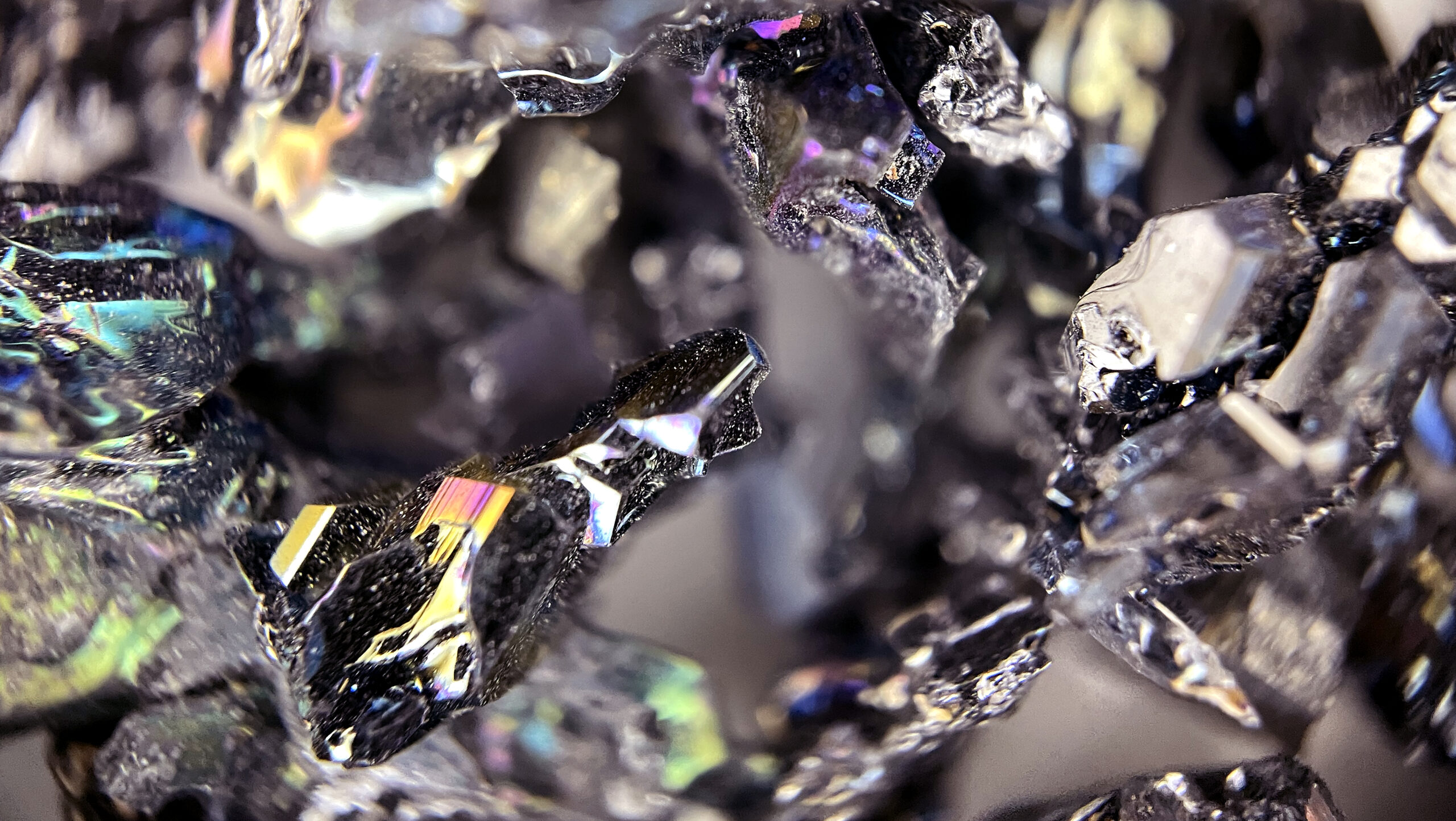

Niobium phosphide is classified as a topological semimetal, which means that its outer surfaces are inherently more conductive than its internal structure. This unique property allows it to maintain high conductivity even when reduced to ultrathin films, a feat that traditional metals like copper struggle to achieve.

Advantages Over Copper

Copper has long been the industry standard for electrical conduction due to its high conductivity and relative abundance. However, as electronic devices become increasingly compact and require finer conductive materials, copper’s limitations become more apparent. When copper is manufactured in films thinner than about 50 nanometers, it begins to lose its efficiency due to increased resistive losses.

In contrast, niobium phosphide excels in this area. Its atomic structure ensures that as the film becomes thinner, the conductivity remains robust, making it a superior choice for the next generation of high-density electronic applications. This includes computer chips, data centers, and other advanced electronic devices where minimizing energy loss is crucial.

Potential Applications

- High-Density Electronics: The ultrathin nature of niobium phosphide films makes them ideal for use in microprocessors and other high-density electronic components, where space and efficiency are at a premium.

- Data Centers: The improved energy efficiency of niobium phosphide can significantly benefit data centers, which rely on millions of chips to store and process information. Even small gains in energy efficiency can lead to substantial savings in operational costs and environmental impact.

- Quantum Computing: The unique properties of niobium phosphide could be leveraged in the development of quantum computing technologies, where precision and minimal energy loss are crucial.

- Flexible Electronics: Due to its thinness and flexibility, niobium phosphide can be used in the development of flexible electronic devices, which are becoming increasingly popular in consumer electronics.

- Advanced Sensors: Niobium phosphide’s high conductivity and thin-film capabilities make it suitable for use in advanced sensors that require precise and efficient signal transmission.

The Cost vs. Energy Efficiency Dilemma

While the initial costs associated with niobium phosphide are higher compared to traditional materials like copper, it’s essential to consider the long-term benefits and savings. Here’s an analysis:

- Long-Term Savings: The initial investment in niobium phosphide can be offset by the significant reduction in energy losses, particularly in high-performance applications. Over time, the savings on energy costs can make up for the higher upfront costs.

- Improved Performance: In scenarios where efficiency is paramount, such as in quantum computing or high-density electronics, the enhanced performance and reduced power consumption of niobium phosphide can lead to better overall system efficiency.

- Reduced Cooling Costs: High-performance electronics generate a lot of heat, which requires significant energy to manage. By using more efficient conductive materials like niobium phosphide, the amount of heat generated can be reduced, leading to lower cooling costs.

- Innovation and Value: Investing in advanced materials can drive innovation, leading to new technologies and applications that may offer greater value and efficiency. As these technologies mature, production costs are likely to decrease, further enhancing the material’s attractiveness.

The Road Ahead

While the discovery of niobium phosphide’s superior conductivity is promising, further research is needed to fully understand its capabilities and potential limitations. Scaling up the production of this material to meet industrial demands and integrating it into existing manufacturing processes will be key challenges moving forward.

Nevertheless, this breakthrough opens exciting possibilities for the future of electronics, offering a path towards more efficient, high-performance devices that could transform industries and improve everyday technology.

Stay ahead in the world of cutting-edge materials science! Subscribe to our newsletter for the latest updates on innovative discoveries and their applications. Don’t miss out on expert insights and industry trends that can give you a competitive edge.